There are two ways of looking at your work. One is as a subtractive process, the other is as an additive process.

Understanding the difference between these two points of view is one of the highest leverage ways to improve your and your team’s effectiveness. Failing to understand it is probably one of the largest sources of waste and frustration in most companies.

So what’s the difference?

A subtractive process works like this: you start with a mountain of stuff to get done.

By the time you’re done, someone will have done all of it. In order to complete the project, each person “subtracts” some of it from the space.

The project is done once everything has been subtracted and the space is full. You’re done when it’s all colored in.

The other way of looking at work is as an additive process.

Consider a factory worker assembling cars. According to the logic of an additive process, if the worker assembles 2 cars in a day, they make the company a profit.

If the worker works harder and assembles 4 cars in a day, they make the company twice as much money. Under additive logic, you can do the same work, but just more of it, and you generate more value.

The root of much organizational and management dysfunction is that most people view their work as additive, but the way in which companies actually generate value is through a subtractive process. Even though work can be viewed as additive, productivity is always and everywhere a subtractive process.

If you are building an apartment complex, the building starts to generate income when it is complete and you can start leasing out the units. This is a subtractive process, not an additive one.

If a plumber lays the piping twice as fast but fails to coordinate with the electrician so the building gets delayed then they think that they have done their job better, but they’ve lost money for the company contracting with them.

The plumber is now annoyed because they see themselves as having worked really hard and gotten something done and the management company is annoyed because the building is delayed. The plumber did faster work, it was more additive, but they were less productive.

In my experience, most software engineers tend to view their work as additive rather than subtractive. They work diligently to build out a robust feature set with lots of functionality. However, they often overlook the jobs-to-be-done of the software. Why is the customer “hiring” this software and what do they actually need?

Oftentimes they don’t need a robust feature set, they just need a simple solution to a specific problem.

The problem in both these examples is that the contributes view their work as additive rather than subtractive. As a result, they tend to make themselves into the wrong shape.

A good shape is one which adds values to the project AND effectively “gels” with the pieces around it.

When someone views their work as additive rather than subtractive, they will often end up doing more work, effectively filling in a larger total area, but they are doing it as a bad shape which makes the overall project less effective.

A functional team looks something like this:

You have individual contributors (say texture artists in this example) that are performing a specific role (green balls) and then you have a manager or team lead (red gooey shape) that is coordinating all their work to go together.

Many new managers make themselves the wrong shape as they struggle from going from filling a solid dot space to meshing things together.

The role of the manager is to maximize the overall effectiveness of their team. That usually means meetings, project management and other managerial tasks to fill in the little spaces between individual contributors as opposed to doing what they used to do in their specialist role. The project doesn’t need another green dot, it needs a red blob to coordinate the green dots.

To get the project done, you’ll have other similar teams – marketing, sales, engineering, etc. and then you’ll typically have a higher management layer that integrates all of them.

This breaks down when some people are viewing their work as additive and others as subtractive. It leads to a dynamic where everyone is working hard, but very little is getting done.

Consider this example of Nick and his manager Gloria. (Neither of them are real people).

Nick is working hard and excited about everything he’s getting done. He feels like he’s doing the best work of his career, cranking out tons of great stuff, going way above and beyond the call of duty. It feels great and he can’t wait for reviews when Gloria will recognize all his effort and contribution.

Until one day, in one of their one-on-ones, Gloria gives Nick a thin-lipped smile and takes a deep breath and tells him that he’s underperforming.

The first thing Nick feels is shock and disbelief. Underperforming? Is this really happening? Then he feels anger: anger at Gloria for not seeing things the way he does. How could she be so blind to all his hard work? Then he feels dejected that his manager’s view of him is so far from his own, and then there’s the wave of self-doubt: maybe his best just isn’t good enough, or maybe this team will just never value his strengths and he’ll have to move on. Resignation starts to set in.

Gloria is just as frustrated, because try as she might to explain what she sees as very basic responsibilities Nick is dropping, it doesn’t seem to stick. All around her things are suffering because of Nick’s negligence, but the message just doesn’t seem to get through to him. When she suggests specifics that he could work on, Nick reacts with exasperation. To him, it seems Gloria is just piling time-consuming minutiae on top of the real, significant contributions already taking up all his time.

If you’ve worked pretty much anywhere, I expect this will sound familiar.

The root problem is that Nick has a bad shape but he doesn’t know it and Gloria hasn’t explained it to him.

Gloria’s role as a manager is to spell out exactly what is expected from a junior employee, with no room for ambiguity so that it is clear what the correct shape is of his work.

Most frequently, the issue is that individual contributors tend to see some of their work as “high value” and other work as low value. From Nick’s point of view “Gloria is just piling time-consuming minutiae on top of the real, significant contributions already taking up all his time.”

In the case of a developer, coming up with creative solutions and writing code seems high value. Meticulously commenting your code seems low value.

For a marketing person, coming up with a new email campaign seems high value. Explaining the role of it to client services so they have the context to onboard the leads it generates seems low value.

The issue is that most work yields knowledge that you need to do other work, and so a viable role that does one of these things must do the other, even if it seems “low value.”

If you’re in charge of writing some code, you also have to comment it. Even though this may seem “low value” work, if you don’t comment it then nobody else will understand it well enough to do it for you.

If you’re in charge of coming up with a creative direction for a project, you also need to spend just as much time communicating it outwards to others so they can be effective at their jobs.

Subtractive productivity means you contribute the most to the final process by being a complete shape that others can work with. Doing more work that is the wrong shape generates zero additional value and likely generates cost.

Like Nick, most people think of productivity as an additive process. They think they are contributing value because they wrote some amazing code or did some incredible mock-ups or designed a great marketing campaign. When they face criticism, they react with indignation: “Didn’t they realize how valuable my addition to the project was?”

From the perspective of the company though, their job isn’t to be additive. It is to be subtractive.

The result is a dynamic that feels like everyone is pulling in slightly different directions. Even if everyone is diligently working hard, very little seems to be getting done.

Writing that great code generated knowledge and understanding that could have given the rest of the team foresight into future challenges the project would face if it were effectively communicated. The failure to do that removes much of the value of the code in the first place.

If Nick had written half as much code and spent the other time commenting the code and communicating those challenges to others on the team, he would have actually been more valuable to the company even though from his own perspective he was doing more lower-value work.

This view of work as an additive process is a legacy of our industrial past. For most of the 20th century, consumer demand outstripped supply and companies focused on mass-producing generic items of moderate quality.

Today, we find ourselves in the near opposite situation with consumers demanding more and more customization and personalization and companies needing to adapt to that.

Henry Ford’s problem was he couldn’t make enough stuff. Jeff Bezos’s problem is that people can only use so much stuff.

This shift around how businesses and production are organized began in the 1970s with the advent of the Toyota Production System. For decades, American automobile companies had cut costs by mass-producing fewer types of cars.

For a long time, consumer demand for automobiles had seemed insatiable and so car manufacturers were busy buying high-performance machines that would allow them to keep up with the growing demand.

When the Oil embargo hit in the early 1970s, car sales slumped and the mass production techniques lead to reduced profitability. Automobile manufacturers were making lots of cars that consumers didn’t want, leading to excess inventory throughout the production process. Cars and parts piled up and profitability slumped.

The Toyota Production System pioneered the idea of just-in-time production. Each week, the sales of customer cars were sent to the factory and a precise production schedule to just make the cars that customers wanted was devised. This required overhauling both the actual physical factory as well as the culture, but it meant less unneeded inventory and higher profitability.

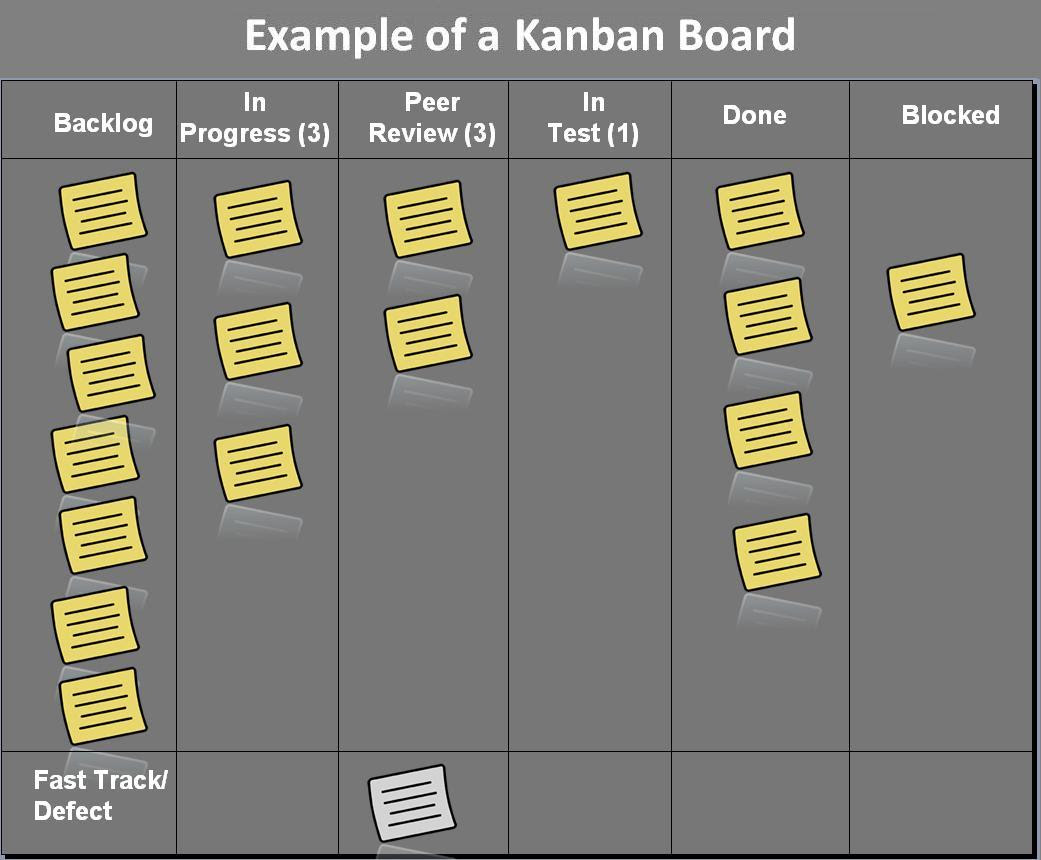

The Toyota Production System is most famous for the creation of Kanban boards (which software services such as Trello have popularized). Kanban provides a helpful visual of how the Toyota Production System works.

Many teams use Kanban, but few use it effectively. It’s the underlying philosophy, not the board itself, that is more important. Kanban, used properly, is a tool for doing subtractive work.

For Toyota, you start with how many cars were ordered then you work back – if 10 engines are required then that order is moved down the Kanban to the engine manufacturing department. Ditto with tires.

Here is Taiichi Ohno, the creator of the Toyota Production System on how Kanban was implemented at Toyota:

The final assembly line is taken as the starting point. On this basis, the production plan, indicating the desired types of cars with their quantity and due date, goes to the final assembly line.

Then the method of transferring the materials is reversed. To supply parts used in assembly, a later process goes to an earlier process to withdraw only the number of parts needed when they are needed.

In this reverse way, the manufacturing process goes from finished product back to the earliest materials-forming department.

Every link in the just-in-time chain is connected and synchronized.

By this, the management work force is also reduced drastically. And kanban is the means used for conveying information about picking up or receiving the production order.

The essential element here is the view of the manufacturing process as subtractive rather than additive process.

Productivity is always and everywhere a subtractive process. The goal is not to make the most stuff, it is to make the right stuff at the right time.

Rather than starting with “make as many cars as possible,” Ohno began with the goal of minimizing waste.

This entailed only producing the exact cars customers wanted when they wanted them then using Kanban to “pull forward” exactly the parts that were needed at exactly the right time.

Just-in-time and Kanban flows are poorly understood and implemented.

The primary reason is that many people that use tools such as Kanban still use them in an additive way. Their goal is to get as many cards moved across the board as possible.

This is precisely what Ohno was fighting against. The goal is not to get as many cards across the board as possible, it’s to get just the right number of cards at just the right time to minimize waste.

This is not the pointThe secondary reason is that just-in-time is understood to mean “hold no inventory or have no slack at all.” An appropriate amount of inventory or slack in the system is not waste, an inappropriate amount is.

If an outside supplier of a part says they need three days lead time to manufacture it, then the Kanban size of that inventory should always be three days worth of material.

If you only order items when needed (e.g. that day), you are not following the Toyota Production System and will need to constantly stop production as the supplier cannot get them there for three days.

Just-in-time also doesn’t preclude storing some inventory when that is strategically valuable. If you know that sometimes a news story will break that increases sales of a particular item by 30% then holding some extra inventory (assuming doing so is not prohibitively costly) is a smart thing to do.

Similarly, well-run teams tend to run at ~80% of their capacity most of the time. This leaves sufficient capacity to absorb shocks when unexpected events pop up (making the system more robust or ergodic).

The Toyota Production System is more well suited to the world today because it was already focused on personalization and better suited to serve the long tail market structure created by the internet. The diversity of consumer demand and the speed at which it shifts has only accelerated over the last fifty years.

Translating subtractive work into a knowledge work context is necessarily more recursive than in manufacturing. You don’t always know the exact end goal and so there is a constant process of updating the size and scope of the “canvas” from which work is subtracted.

I use a quarterly planning and weekly review process and this concept fits into them neatly. Each quarter I am scoping the canvas to the best of my ability then I am adjusting my shape or my teams’ shape on a weekly basis to most effectively accomplish the quarterly objectives.

The key though is not these processes, but the view of productivity as a subtractive process. There are many other that understand this and do it differently than I do but are still very productive.

What are some ways you can apply this?

For individual contributors – it’s worth thinking about how your work fits into the overall subtractive process your team is working on. What things could you do to make the shape of your work more correctly gel with your team? Oftentimes, these are tasks that may seem low value and not worth your time but are essential to helping the team work well together.

Most commonly in my experience, it’s communication such as commenting on your code for a developer, explaining the rationale behind a marketing campaign or updating a Standard Operating Procedure. Your job is not to get the most work done possible, it’s to help the team accomplish their objectives most effectively – subtract, subtract, subtract.

For managers, it’s important to first help your reports understand that their work is subtractive. Their job is to fill a certain space on the canvas of the projects they are working on, not just do as much work as possible.

The role of a good manager is to make it crystal clear what shape each of your direct reports should be such that there is no ambiguity about what is expected. An important part of this is, again, communication.

Don’t just delegate tasks, talk about the whole project, including things that seem totally irrelevant. In order for someone to fill a subtractive space, they must deeply understand the space everyone around them is filling. Give them the context they need to autonomously and effectively complete their role then push the responsibility down the chain.

This post was inspired by this post from Tynan as well as Taichi Ohno’s Toyota Production System. Both are paraphrased liberally here and it’s very worth reading the originals.

Last Updated on June 6, 2025 by Taylor Pearson